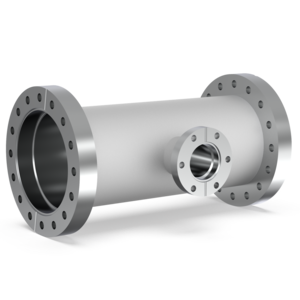

Reducing T-Piece rotatable - St St DN 100 CF - DN 40 CF, C10009551

Variant

Explore the range of variants given below to compare the product

| Short Description | Part Number | Connection Vacuum Hardware Fittings |

|---|---|---|

| C10005350 | DN 40 CF (2.75") DN 40 CF (2.75") DN 16 CF (1.33") | |

| C10007551 | DN 63 CF (4.5") DN 63 CF (4.5") DN 40 CF (2.75") | |

| C10009551 | DN 100 CF (6") DN 100 CF (6") DN 40 CF (2.75") | |

| C10011552 | DN 160 CF (8") DN 160 CF (8") DN 63 CF (4.5") |

Components and Fittings CF

When you buy vacuum pump components from Edwards, you can expect the quality and service that only a leading international supplier can provide. We understand that flanges and fittings are critical to the performance of your vacuum system, and supply only high quality products which meet the highest specification.

CF fittings have a unique sealing system to achieve a leak tight joint. A copper seal is squeezed axially and radially between two CF flanges, where knife-edges force the copper to cold flow. This flow is severely limited by the vertical flange wall which generates high pressures and fills surface imperfections to prove an extremely tight metal to metal seal.

Metric flanges, common in Europe and Asia, use metric tapped holes and bored holes in flanges suitable for metric tubing. Flanges specified in inches, more commonly used in the USA, use UNF flange threads and bored holes compatible with inch sized tube. We offer both options.

Our components and flange fittings are designed to be leak-tight across the range of vacuum applications, and not intended to provide full structural support. When designing any vacuum system, it is essential that consideration is given to the static and dynamic loads imposed on each connection. If necessary, additional mechanical support should be provided and built into the design. Regular inspection including leak-checking and, where appropriate, periodic replacement of components should be considered to ensure system efficiency and safety is maintained.

Features and Benefits

- Convenience of supply - Single source supplier, able to provide the complete system solution either online or via local supply centres.

- High quality and reliability - Precision material control ensures a dependable vacuum performance on sensitive or demanding applications.

- Comprehensive choice - Complete range for all common flange sizes in aluminium and stainless steel.

- Manufactured to ISO 3669 standard

- Nominal diameters 16-350 mm

- Used almost exclusively with copper ring metal seals

- Typically used in UHV systems: pressures < 10-8 mbar

Environmental Conditions

| Temperature Ambient Operation Max | 573.15 |

| Temperature Ambient Operation Min | 77.15 |

General Product Information

| Connection Vacuum Hardware Fittings |

DN 100 CF (6")

DN 100 CF (6") DN 40 CF (2.75") |

| Recommended Pressure Range Min | 1.000 × 10⁻¹⁰ |

| Recommended Pressure Range Max | 1.000 × 10⁵ |

Material of Construction

| Material Body | Stainless Steel 1.4306 / 304L / X2 CrNi 19 11 |

| Material of Construction | Stainless Steel 1.4306 304L |

| Material Abbreviation | St St |

Classification

| Classification Product Pressure Range | Ultra High Vacuum: 1·10⁻⁷ - 1·10⁻¹¹ mbar |

Variants

| Variant Connection Vacuum Flange Rotatable | Rotatable - CF |